Obakki – A Purpose-Led Lifestyle Brand and Foundation

Founder Treana Peake, supports artisan partnerships and funds development work through the Obakki Foundation.

Founder Treana Peake, supports artisan partnerships and funds development work through the Obakki Foundation.

Trained as a scientist and ornithologist, Dr. Gray is the first woman to hold the title of CEO in the organization’s 117-year history.

Latitude Craft Chocolate is a sustainable and transparent bean-to-bar chocolate company made at its origin in Uganda.

Steven Peck is dedicated to creating greener, healthier & resilient cities with nature & urban agriculture.

Creating an equitable spice trade by disrupting an outdated trade system and putting money and power into the hands of Indian farmers.

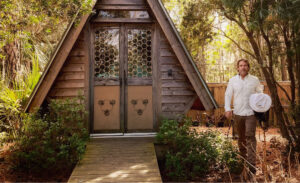

Helping to save the bees by building hives, pollinating flowers, powering food supply, and spreading beauty.

Leading sustainable architect working on scalable innovations to deliver on Google’s 2030 Carbon aspirations and the hybrid future workplace.

Arno Adkins is Partner at COOKFOX, an architectural studio dedicated to integrated, environmentally responsive design.

Solar Sister is investing in women entrepreneurs to deliver clean energy directly to homes in rural African communities.

Seattle-based beauty company Kari Gran is a women-owned organic skincare brand that prioritizes sustainability.

Environmental artist Justin Brice encourages others to take a critical look at the relationship between humans and the planet.

Founded by Helen and Mike Cameron, Uncommon Ground is America’s first certified organic rooftop farm.

Miranda Massie, the director of the Climate Museum in NYC, strives to inspire action on the climate crisis through the arts and sciences.

FORESTIS is a luxury, eco-conscious retreat nestled in the beautiful Dolomite Mountains of Italy.

Located outside of Paso Robles, California, Villa Creek Winery prioritizes the cultivation of organic and biodynamic wine.

Air Company is a technology and design start-up that strives to redefine how sustainability looks and feels in the consumer lifestyle industry, in part by transforming CO2 into impurity-free alcohol.

How Kent Lindvall and Britta Jonsson-Lindvall created eight unique Swedish tree houses, interweaving design and sustainability.

KAJ Hotel is a sustainable, simple two- to four-person houseboat hotel located in the Holmen neighborhood of Copenhagen, Denmark.

Founded in 1973, Cakebread Cellars is a family-owned business in Napa Valley, CA that utilizes sustainable vineyard practices.

Ecosia, founded by Christian Kroll, is a sustainable search engine that turns searches into trees and is notably the first-ever German B-Corp.

ÁBBATTE creates handmade textiles in Spain on the grounds of a 13th -century Cistercian monastery in the town of Segovia.