Diaspora Co – Building a Better, Equitable Spice Trade

Creating an equitable spice trade by disrupting an outdated trade system and putting money and power into the hands of Indian farmers.

USA

Monica Janvier November 10, 2020

Since founding the mission-driven, environmental vertical farming company AeroFarms in 2004, co-founders Marc Oshima and David Rosenberg have revolutionized traditional agriculture. AeroFarms was recently named one of the World’s Most Innovative Companies by Fast Company three times and one of TIME’s 2019 Best Inventions. Utilizing their patented and award-winning aeroponic technology, AeroFarms grows plants locally and safely in urban areas. They’re able to grow year-round, using fully-controlled environments, no soil, no pesticides, and 95% less water than traditional field farming. As a certified B Corporation, AeroFarms values both social and environmental impact. This mission-driven environmental company not only impacts communities—building farms in urban areas, addressing food deserts, and creating jobs—but also positively impacts the environment by reducing food miles and carbon emissions, among many other cautious decisions.

Mood of Living: Where did you grow up?

Marc Oshima: I grew up in Morristown, NJ and my father worked in Newark, NJ. Our global headquarters are in Newark, NJ and I am proud that we are reimagining the Garden State for agriculture.

Mark Oshima and David Rosenberg

MoL: Where did you go to school? What did you study?

MO: I went to Columbia University where as an undergraduate I studied East Asian Studies. The diversity of thoughts and cultures is a really important element to lead business today. I also have my MBA from Columbia as well.

MoL: What was your first job?

MO: My first job was working in market and media research, sparking my love for marketing and understanding how to connect with the consumer and build brands and businesses effectively.

MoL: Where did you meet? How did you both combine your expertise to build AeroFarms?

MO: David and I first met through the sport of fencing where we represented the United States in competitions all over the world. We always looked for ways to work together and AeroFarms was the perfect opportunity to combine his environmental stewardship along with my passion for feeding communities.

The inspiration for AeroFarms is manyfold. We have major macro issues for agriculture-related to climate change, depleting water sources, loss of arable land, over-dependence on the use of pesticides, increasing food safety recalls, and massive population growth and urbanization. We need a new paradigm and our mission is to grow the best plants possible for humanity. Our indoor vertical farms use aeroponics to be able to grow with up to 95% less water and zero pesticides vs. field farming.

Our work is very much a lifestyle and choice of what I consciously consume. I am also on the board of directors for the Produce Marketing Association, a global organization focused on increasing consumption of healthy produce and Chefs Collaborative, a 26-year-old non-profit focused on a more sustainable food system that was founded by leaders like Alice Waters and Rick Bayless.

MoL: What inspired you to build AeroFarms? What global problems does AeroFarms strive to solve? How does it do this?

DR: Seventy percent of global water resources go toward agriculture. 70% of freshwater contamination comes from agriculture. That stat drove me to co-found AeroFarms. I wanted to do something about the very real possibility that my children would not be able to take clean water for granted, as most of us do today. To accomplish this, I learned that salad is a good place to start. The US packaged salad industry will grow to $7 billion by 2018 and 95% of those greens grow in either the Salinas Valley in California or Yuma, Arizona. The quantity of water required to sustain these farms, not to mention the intense water requirements of the controversial “triple washing” practice, has largely contributed to the dire state of water in California, magnified — though not begun — by years of drought. Driven by a goal to create a company that could change the world and how to interact with our food systems, I partnered with Dr. Ed Harwood and Marc Oshima to create AeroFarms as we know it today. AeroFarms patented growing technology and expertise was initially developed in Ithaca in 2004 by Dr. Edward Harwood, a former professor at Cornell University, one of the top agriculture sciences research universities in the world. In 2011, I joined forces with Ed and our CMO and Co-Founder, Marc Oshima, to scale AeroFarms technology and fundamentally transform the food system in the process.

MoL: What are the benefits of vertical farming? And how does it differ from traditional agriculture?

MO: Our indoor vertical farms are fundamentally changing the way food is grown and transported, with a keen eye on food supply chain needs. First, we disrupt traditional supply chains by building farms on major distribution routes and near population centers, significantly reducing carbon emissions incurred from leafy greens trucking and distribution, which is the current industry norm. We grow using 95% less water than field farmed food with zero harmful runoff, zero pesticides and significantly less fertilizer, mitigating or totally eliminating any harm to the surrounding environment. Moreover, our environmentally controlled indoor farms can grow all year round independent of climate and weather events. This means we don’t have to worry about frost or crop protection and can grow just about any crop by replicating their ideal environment in our aeroponic vertical towers.

Here’s why that’s so important: over the last 40 years, we have lost 30% of our arable land, and globally, 70% of our freshwater goes to agriculture, and 70% of our freshwater contamination comes from agriculture, leading to dead zones and dramatically harming natural ecosystems. In the United States, most of our fresh leafy greens supply comes from California or Arizona and must be transported over thousands of miles every day to reach its destination, emitting harmful carbon emissions and leading up to over 75% food waste along the supply chain. In 2050, it is estimated that close to 70% of the world’s population will be living in megacities around the world, close to 9 billion people. The UN estimates we will need up to 50% more food to feed this growing population.

At AeroFarms, we’re innovating to do things differently and create a more sustainable fresh food system. We are a certified B Corporation and mission-driven company growing commercial plants indoors with 390 times greater productivity per square foot annually vs. traditional field farming while using 95% less water and zero pesticides. We use the latest sensing technologies & data science, as well as tools such as machine vision and AI to fulfill our mission: to grow the best plants possible for the betterment of humanity, as close to people as possible. Consumers can feel confident knowing plants grown in our indoor vertical farm are grown with the least environmental impact and with freshness and flavor as a priority.

MoL: What products do you grow? How are they grown?

MO: Since we began in 2004, we have grown over a thousand unique varieties of leafy greens alone in addition to dozens of other crops. We are collaborating with top chefs and buyers to bring distinct offerings to market. As world experts in growing from seed to package and technologists, we have built a fully controlled farming approach that has enabled us to translate hundreds of millions of plants into billions of data points to inform optimal growing, quality and nutrition. That means the most flavorful, fresh greens are grown year-round in our indoor vertical farm – our kale is sweeter and our crowd-favorite arugula is perfectly peppery. Our greens, Dream Greens by AeroFarms, is available across the Northeast at select Whole Foods Markets, ShopRite Stores, and via FreshDirect & AmazonFresh.

MoL: What sets your company apart from other vertical farming companies?

MO: As the only indoor vertical farm that is B Corp Certified, we are proud to put purpose first and we take our commitment to our community, customers and team members as the priority. We support our communities in every way we can – we hire locally, pay fair wages, and work with schools to connect kids to what’s on their plate – and we’re constantly evaluating our best practices and process to ensure our day one commitment to “purpose” remains the priority. Additionally, a second way we stand out is expertise. With 14 years of expertise in the relatively new industry, we have created an expert team of plant scientists, engineers, innovators and farmers harnessing over a decade of company knowledge to grow the best plants possible for the betterment of humanity.

MoL: What is the aeroponic system? How does it work?

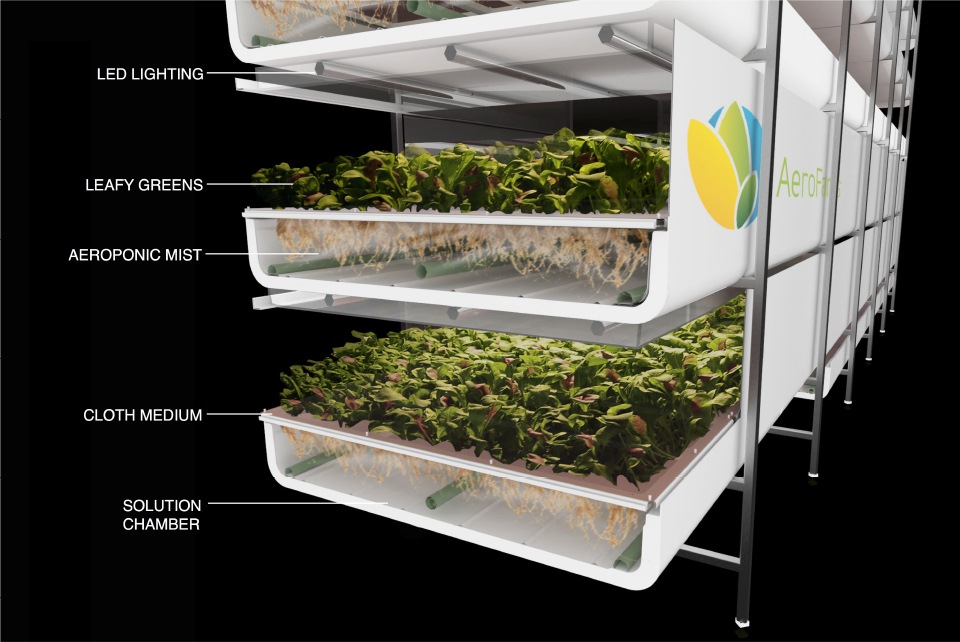

DR: Aeroponics is a form of soilless hydroponic growing that requires even less water, therefore offering a way to grow plants with the least amount of natural resources. Dr. Ed Harwood, the innovator of the AeroFarms grow system, is a true pioneer in the field of aeroponics and guides the company as our Chief Science Officer today. Here’s how the system works – the vertical platforms are modular and scalable for use in indoor farms. Our proprietary aeroponic technology can be integrated with automation and our stacked, multilayered growing platform can be used for separate harvesting of plant leaves, stems, and roots, allowing full utilization of the plants and while also mitigating waste.

MoL: As a recipient of the 2018 inaugural Global SDG Awards, what SDGs do you implement in your business?

MO: Our company’s mission and activities are in alignment with the United Nations’ Sustainable Development Goals, particularly Goal #2, to achieve Zero Hunger by 2030: to end hunger, achieve food security and improved nutrition and promote sustainable agriculture for all.

One way to achieve Zero Hunger is to waste less food along the supply chain through local indoor vertical farming. Approximately 40% of all food is wasted, and this is even more egregious along the leafy greens supply chain, where there is up to 76% waste. By growing and distributing food locally, we are helping to minimize and eliminate food waste altogether.

Another way to achieve Zero Hunger by 2030 is to do more with less. At AeroFarms we grow on a fraction of the land, reusing abandoned space in and around cities to grow at 390X more productivity than field farming. We disrupt traditional produce supply chains by building farms near major distribution routes and cities, minimizing harmful carbon emissions, and defying traditional growing seasons by enabling local farming at commercial scale all-year round. Moreover, our patented precision farming technology allows us to use a fraction of the fertilizers and 95% less water than field farming.

Finally, we need to shift what we eat as a global community and must adopt a healthier and more environmentally sustainable diet with a plant-based focus. Quick, nutritious meals full of locally grown greens are one way to do just that.

MoL: What does social responsibility mean to you?

DR: Social responsibility is in our DNA. Since Day 1, AeroFarms was founded on a holistic, cohesive social responsibility strategy from how we treat and pay employees, to being a positive addition to the community, to offering a sustainable solution to agriculture. As a B Corp Company, we ensure every facet of people, planet and purpose is at the core of every venture we do.

MoL: Why did you relocate your headquarters to Newark, NJ? What benefits does this provide to local communities?

MO: We are proud to be active members of the Newark community. We hire locally with fair wages, support a local school through an AeroFarms unit in their Dining Hall to gain access to fresh, healthy food with hands-on learning, and support several local community organizations by supplying fresh greens.

MoL: AeroFarms recently partnered with the City of Jersey City to launch the nation’s first municipal vertical farming program. What motivated this decision to partner? What does this mean for Jersey City communities?

DR: We are excited to partner with The City of Jersey City and the World Economic Forum to bring healthy, nourishing greens to Jersey City residents via the first-ever city-wide vertical farming program in the country. This program, part of the WEF’s Healthy Cities & Communities 2030 Initiative, will build small AeroFarms vertical farming units throughout Jersey City located in senior centers, schools, public housing complexes, and municipal buildings and will grow hyper local, pesticide free, nutritious leafy greens all year round. Our motivation to create the partnership is to help create more distributed, localized food production systems. We need new ways to get healthy food to our most disadvantaged members of society and we’re here to find better solutions.

MoL: What are some obstacles you encountered when building AeroFarms? What are the most important lessons you learned?

MO: As a scaling business, we are always balancing priorities and resources and need to understand how to focus on the areas with greatest returns. We have had to learn to say “no” to keep on track.

MoL: What are your future plans for continuing to address food inequity? Where do you plan on building farms next?

DR:We have several exciting projects in the pipeline – our next project will be a 90,000 square foot indoor vertical R&D farm, the largest of its kind in the world, located in Abu Dhabi. The farm will be dedicated to state-of-the-art R&D and commercialization of relevant local crops utilizing AeroFarms’ expertise and proprietary indoor vertical farming technology. Additionally, we’re also working on interesting projects to address food access, equality and decrease food waste. One of our other projects is a vegetable stew made with our sustainable second-harvest of stems and greens in partnership with Matriark Foods and Table to Table through the ReFED COVID-19 Food Waste Solutions Fund to deliver 500,000+ meals and offset 1,000,000+ pounds of greenhouse gases to help feed the New Jersey community.

MoL: What advice would you give to someone starting their own sustainable and socially responsible business?

DR: The best decision we made in the last five years was ensuring that we hire not only for experience but also cultural fit. Experience is absolutely crucial to contributing to any company, and we value it highly. Simultaneously, it is important to hire for cultural fit to ensure that our employees both enjoy the work that they are doing and supporting our values at a mission-driven company.

Photography courtesy of AeroFarms

Creating an equitable spice trade by disrupting an outdated trade system and putting money and power into the hands of Indian farmers.

Founded by Helen and Mike Cameron, Uncommon Ground is America’s first certified organic rooftop farm.

Ecosia, founded by Christian Kroll, is a sustainable search engine that turns searches into trees and is notably the first-ever German B-Corp.